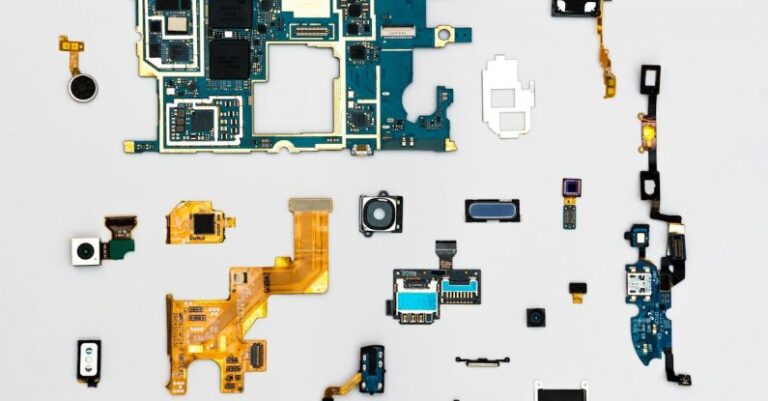

Building a remote-controlled (RC) robot can be an exciting and rewarding experience for hobbyists and enthusiasts alike. One crucial aspect to consider when constructing an RC robot is the choice of materials. The materials used can greatly impact the durability, performance, and overall functionality of the robot. In this article, we will explore some of the best materials for RC robot construction that can help you create a sturdy and efficient robot for your projects.

**Aluminum: Lightweight and Durable**

Aluminum is a popular choice for building the frame of an RC robot due to its lightweight nature and exceptional durability. This material is known for its strength-to-weight ratio, making it ideal for constructing a sturdy yet agile robot. Aluminum frames are less likely to bend or break under stress, providing stability and longevity to the robot. Additionally, aluminum is corrosion-resistant, ensuring that your robot will remain in top condition even after prolonged use.

**Carbon Fiber: Strength and Flexibility**

Carbon fiber is another excellent material for RC robot construction, offering a unique combination of strength and flexibility. This advanced material is lightweight, yet incredibly strong, making it ideal for building robust and high-performance robots. Carbon fiber frames can withstand impact and vibrations while maintaining their structural integrity, providing a reliable foundation for your robot. Moreover, carbon fiber offers flexibility, allowing for intricate designs and customization options to suit your specific requirements.

**Plastic: Versatile and Cost-Effective**

Plastic is a versatile and cost-effective material commonly used in RC robot construction. While not as strong as aluminum or carbon fiber, plastic offers a good balance of durability and affordability. Plastic components are lightweight and easy to mold, making them suitable for various robot parts such as wheels, gears, and casings. Additionally, plastic is available in a wide range of colors and finishes, allowing for customization and personalization of your robot.

**Steel: Robust and Resilient**

Steel is a durable and robust material that is often used for heavy-duty RC robots that require extra strength and resilience. Steel frames provide excellent protection and support for the internal components of the robot, ensuring stability and durability in challenging environments. While steel is heavier than aluminum or carbon fiber, it offers superior impact resistance and durability, making it suitable for rugged terrain and demanding tasks.

**Brass: Precision and Stability**

Brass is a metal alloy that is valued for its precision machining capabilities and stability, making it a popular choice for certain components in RC robot construction. Brass components such as gears, bearings, and connectors offer smooth operation and consistent performance, enhancing the overall efficiency of the robot. Additionally, brass is corrosion-resistant and has excellent electrical conductivity, making it suitable for various applications in RC robotics.

**Conclusion: Crafting Your Ideal RC Robot**

In conclusion, selecting the right materials for RC robot construction is essential for creating a durable, efficient, and high-performing robot. Aluminum, carbon fiber, plastic, steel, and brass are among the best materials to consider based on your specific needs and preferences. Whether you prioritize lightweight agility, strength and flexibility, cost-effectiveness, robustness, or precision, there is a material that can help you craft your ideal RC robot. By choosing the right materials and combining them strategically in your robot design, you can build a robot that meets your requirements and exceeds your expectations in terms of performance and durability.