Designing a 3D-Printed RC Robot

When it comes to creating a 3D-printed RC robot, the possibilities are endless. The fusion of technology and creativity allows you to build a unique and functional robot that can be controlled remotely. In this article, we will explore the steps and considerations involved in designing a 3D-printed RC robot.

Choosing the Right Design Software

The first step in designing a 3D-printed RC robot is selecting the right design software. Software such as Tinkercad, Fusion 360, or SolidWorks can help you bring your robot design to life. These tools offer a range of features and functionalities that make it easy to create complex and intricate designs. Consider your familiarity with the software and the specific requirements of your robot design before making a choice.

Creating a Conceptual Design

Before diving into the detailed design process, it is essential to create a conceptual design of your RC robot. This involves sketching out the basic structure, components, and functionalities of the robot. Consider the size, shape, and maneuverability of the robot to ensure that it meets your requirements and objectives. The conceptual design will serve as a blueprint for the detailed design phase.

Designing the Components

Once you have a clear conceptual design, you can start designing the individual components of your RC robot. Consider the mechanical and electronic components that will be required, such as the chassis, wheels, motors, and circuitry. Pay attention to the dimensions, tolerances, and interlocking mechanisms of the components to ensure a seamless assembly process. Utilize the design software to create 3D models of each component before proceeding to the printing phase.

Testing and Iteration

After designing the components, it is crucial to test the individual parts and the overall assembly of the RC robot. Conduct thorough testing to identify any design flaws, mechanical issues, or compatibility issues between components. Iterate on the design based on the test results to improve the functionality, durability, and performance of the robot. Testing and iteration are essential steps in refining the design and ensuring a successful final product.

Selecting the Right Materials

Choosing the right materials for 3D printing is critical in ensuring the quality and durability of your RC robot. Consider the mechanical properties, strength, flexibility, and weight of the materials when making a selection. Common 3D printing materials include PLA, ABS, PETG, and nylon, each offering unique characteristics that can influence the performance of the robot. Select materials that are compatible with your design requirements and budget constraints.

Assembling the RC Robot

Once you have 3D printed all the components of your RC robot, it is time to assemble them into the final product. Follow the assembly instructions carefully, ensuring that each component is correctly positioned and secured. Test the functionality of the robot at each stage of the assembly process to identify any issues or malfunctions. Pay attention to the wiring, connections, and alignment of the components to ensure a smooth and efficient operation of the robot.

Fine-Tuning and Customization

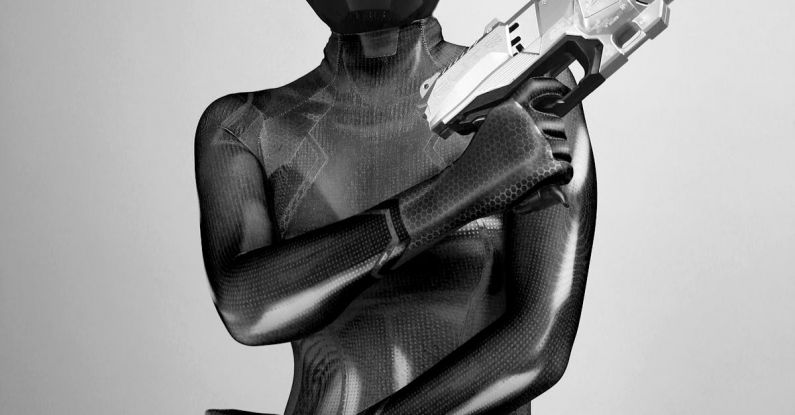

After assembling the RC robot, take the time to fine-tune its performance and appearance. Adjust the motor speeds, steering mechanisms, and control systems to optimize the robot’s functionality and responsiveness. Consider adding custom features such as LED lights, cameras, or sensors to enhance the capabilities of the robot. Personalize the design with colors, decals, or accessories to give your RC robot a unique and distinctive look.

Conclusion: Showcasing Your Creation

Designing a 3D-printed RC robot is a rewarding and creative process that allows you to explore the possibilities of technology and innovation. By following the steps outlined in this article, you can design and build a functional and impressive RC robot that showcases your skills and imagination. Embrace the challenges and opportunities that come with designing a 3D-printed RC robot, and enjoy the journey of bringing your creation to life.